Solar Thermal – How Solar Water Heaters Work

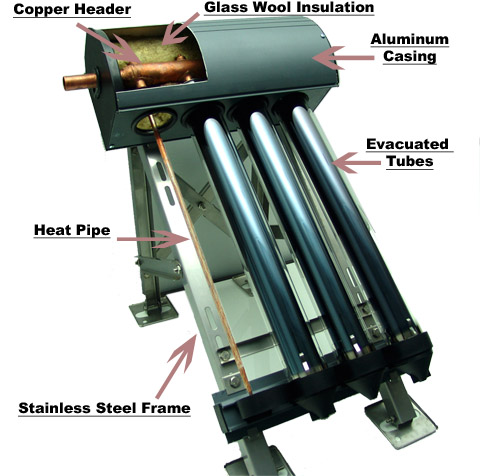

1.Thermal Collectors: Heat Pipes & Evacuated Tube Technology

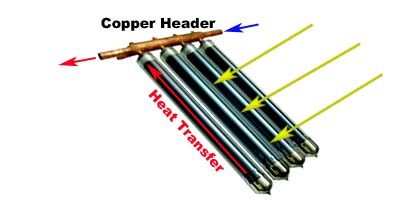

The operation of the solar collector is as follows:

- Solar Absorption: Solar thermal energy is absorbed within the evacuated tubes and is converted into usable concentrated heat.

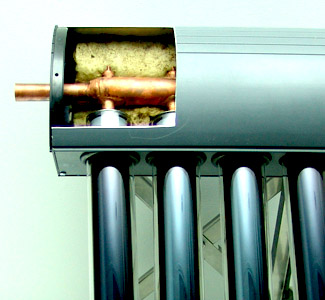

- Solar Thermal Transfer: Copper heat pipes transfer the thermal energy from within the solar tube into the copper header.

- Solar Thermal Storage: A thermal transfer solution (water or glycol mixture) is pumped through the copper header. As the solution circulates through the copper header the temperature is raised by 5-10 °C / 9-18 °F.

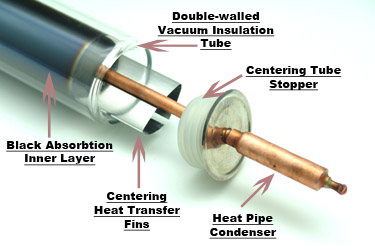

Evacuated Tubes: The most efficient thermal collector on the market, the glass tubes absorb solar thermal energy for use in water heating. The tubes have a double wall, the area between the inner and outer layers of the wall are evacuated ( a vacuum). This acts as a thermos to keep heat from escaping into the atmosphere.

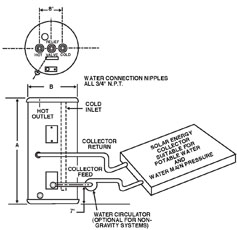

Solar Water Heater(Heating Cycle Diagram Below)

The evacuated tubes are glass tubes manufactured from strengthened borosilicate glass. The tubes have a double outer layer; the outer layer is fully transparent to allow solar energy to pass through unimpeded. The inner layer is treated with a selective optical coating which causes energy absorption without reflection. The inner and outer layer are fused at high temperatures at the end leaving an empty space between the inner and outer layers. All air is pumped out of the space between the two layers (evacuation process) creating the thermos effect which stops conductive and convective transfer of heat which might otherwise escape into the atmosphere. Heat loss is further reduced by the low-emissivity nature of the type of glass that is used.

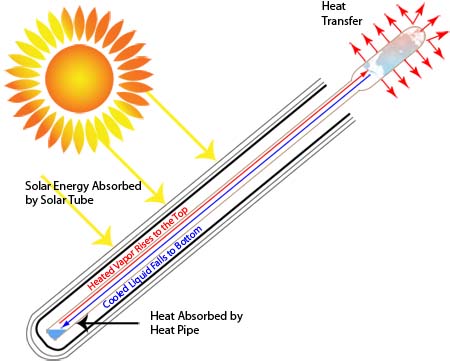

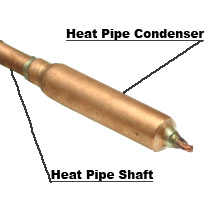

Heat Pipe: Inside the glass tube is the copper heat pipe. It is a sealed hollow copper tube that contains a small amount of proprietary liquid, which under low pressure boils at a very low temperature. In fact the liquid contained in the heat pipe boils at only 86 °F (30 °C).

This heat pipe rapidly and efficiently transfers the captured thermal energy through the evacuated tube and delivers it to the manifold (header) as the liquid boils and rises. As the heat is removed from the heat pipe by the copper header, the liquid condenses and gravity returns it to the base of the heat pipe so that the process is continually repeated.

Because the evacuated tubes are round, they serve as a passive tracking solar collector maximizing their performance.

2. Solar Heat Exchanger Tanks

- Brass valves and components

- Includes temperature and pressure relief valve

- Collector feed and return fittings located at

front of tank for convenient installation - Highly efficient tank design

- Highly efficient heating element

- Prolonged tank life due to specially designed inner tank lining that resists corrosion

- Copper tube heat exchanger

- Bottom inlet for cold water to prevent mixing with hot water

- Easily accessible inlets, outlets, valves and

anode rod to quick install. - Automated temperature control valve

- Temperature overheat protection

The solar heat exchanger tank stores 80 or 120 gallons of solar heated water depending on model selected. Typically the heat exchanger tank sits between the city/well water supply and the customers existing tank.

When hot water is drawn from the existing tank, it is replaced by water from the solar tank that is already hot, meaning that the heating elements or gas burner of the existing tank do not have to operate.

3. Solar Pumping Station, Pumps & Controllers

Tying the collectors and the tank together is a system that consists of valves, a controller, and a pump.

Options are available to configure the system using a pre-configure pump-station (left), or design it with best-of-breed components (right).

Our installers use both methods, depending on the application.